Honeywell XNX Gas Detector Calibration Solutions

Introduction to Honeywell XNX Gas Detector Calibration

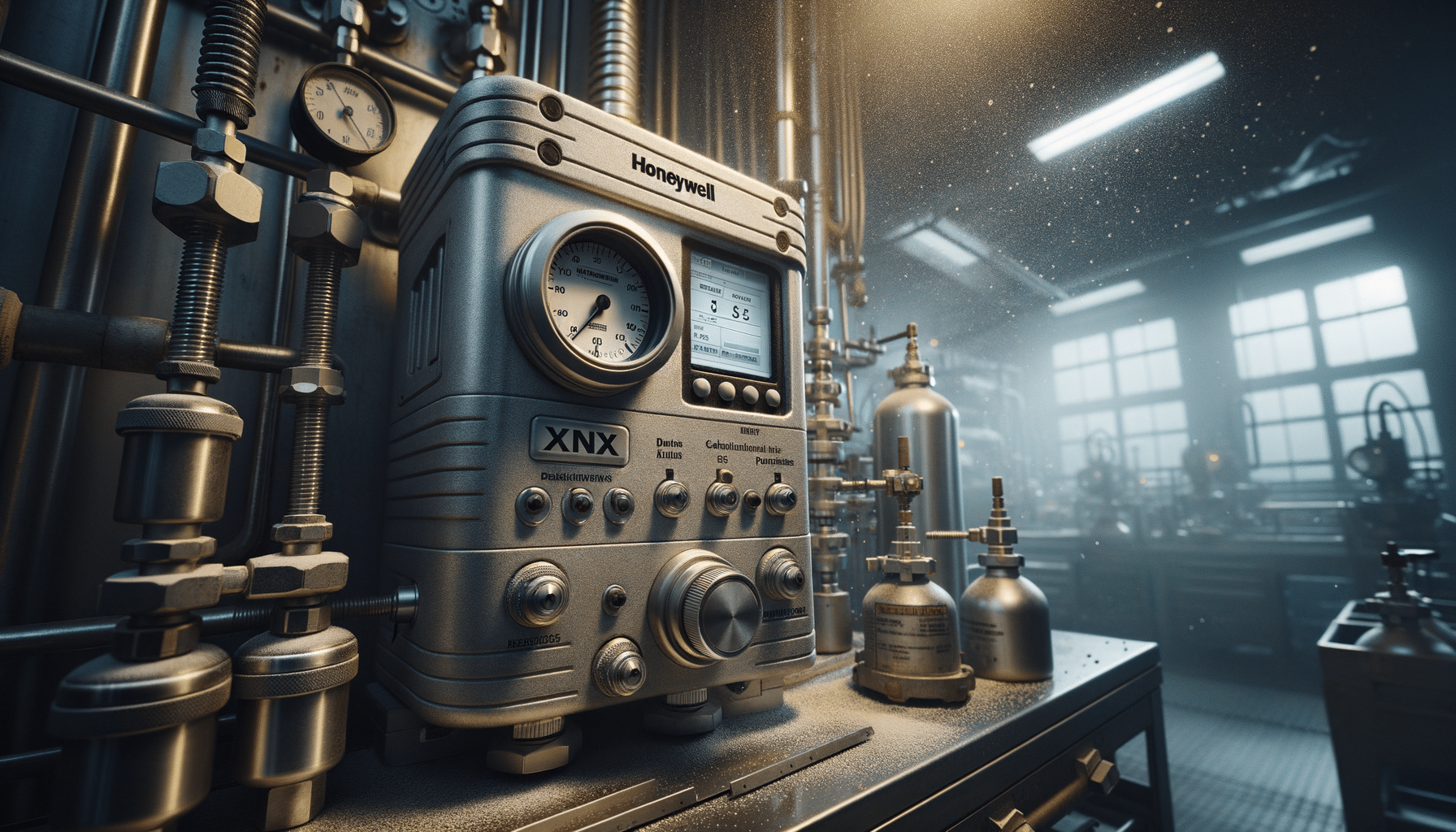

In the realm of industrial safety, accurate gas detection is paramount. The Honeywell XNX Gas Detector is renowned for its reliability and precision in monitoring potentially hazardous gases. However, to maintain its effectiveness, regular calibration is essential. Calibration ensures that the gas detector provides accurate readings, thereby safeguarding the workplace and its occupants. This article delves into the importance of calibration, the methods employed, and the equipment used to achieve optimal performance of the Honeywell XNX Gas Detector.

The Importance of Regular Calibration

Calibration is a critical process in maintaining the efficacy of gas detectors. For Honeywell XNX Gas Detectors, regular calibration is not just a recommendation but a necessity. The sensors within these detectors can drift over time due to environmental factors, sensor aging, or exposure to high concentrations of gas. Regular calibration corrects any sensor drift and ensures that the detector provides accurate and reliable data.

Regular calibration offers several benefits, including:

- Ensuring compliance with safety standards and regulations.

- Preventing false alarms that can lead to costly shutdowns.

- Enhancing the longevity and performance of the gas detector.

- Providing peace of mind to workers and management about their safety.

By adhering to a consistent calibration schedule, industries can ensure their Honeywell XNX Gas Detectors operate at peak performance, thereby mitigating potential risks associated with gas leaks.

Methods of Calibrating Honeywell XNX Gas Detectors

Several methods can be employed to calibrate Honeywell XNX Gas Detectors, each with its own set of advantages. The most common methods include zero calibration, span calibration, and bump testing.

Zero Calibration: This method involves adjusting the detector in a clean air environment to ensure that no gas is present. It sets a baseline for the detector to recognize the absence of targeted gases.

Span Calibration: Span calibration involves exposing the detector to a known concentration of gas to verify that it reads accurately. This method is crucial for ensuring the detector’s accuracy in real-world conditions.

Bump Testing: A quick test that exposes the detector to a small amount of gas to ensure that it responds correctly. While not as thorough as a full calibration, bump testing is a valuable routine check.

Each method plays a vital role in maintaining the detector’s accuracy, and often, a combination of these methods is used to ensure comprehensive calibration.

Equipment Used in Calibration

The calibration of Honeywell XNX Gas Detectors requires specific equipment to achieve accurate results. Key equipment includes calibration gas cylinders, regulators, and docking stations.

Calibration Gas Cylinders: These contain a known concentration of gas used during span calibration. The precision of the gas concentration is crucial for accurate calibration.

Regulators: Regulators control the flow of calibration gas from the cylinder to the detector, ensuring a consistent and accurate application of gas.

Docking Stations: Some advanced calibration systems include docking stations that automate the calibration process, reducing human error and increasing efficiency.

Using the right equipment is essential for effective calibration, ensuring that the Honeywell XNX Gas Detector remains a reliable tool in gas monitoring.

Conclusion: Ensuring Safety Through Calibration

In conclusion, the calibration of Honeywell XNX Gas Detectors is a critical process that ensures the safety and efficiency of industrial operations. By understanding the importance of regular calibration, employing various methods, and using the proper equipment, industries can maintain the accuracy and reliability of their gas detection systems.

Regular calibration not only complies with safety standards but also enhances the confidence of workers and management in the safety measures in place. As technology advances, the methods and equipment for calibration continue to evolve, offering even more reliable solutions for maintaining the performance of Honeywell XNX Gas Detectors.