kitchen remodeling a comprehensive planning guide

Outline:

1) Set the Vision, Budget, and Scope

2) Layout & Space Planning: Flow, Ergonomics, and Safety

3) Materials and Finishes: Durability, Maintenance, and Style

4) Systems that Make It Work: Electrical, Lighting, Plumbing, and Ventilation

5) Conclusion and Next Steps: From Plan to Punch List

Set the Vision, Budget, and Scope

A successful kitchen remodel begins with clarity: what do you cook, how many people use the space, and what frustrations do you want to eliminate? Frame your vision in practical terms—more prep space, improved storage, better lighting, or an open sightline to the living area. Tie these goals to measurable requirements. For example, “more prep space” might translate to a continuous 48–60 inch stretch of uninterrupted countertop, while “better storage” could require full-extension drawers, pull-outs for pans, and a tall pantry cabinet. Define your decision-making lens early: function first, then finishes.

Budget anchors the dream to reality. Typical cost allocation for a full remodel often looks like this: cabinetry 25–35%, labor 20–35%, appliances 10–20%, countertops 10–15%, plumbing and electrical 10–15%, flooring and finishes 10–15%, with design, permits, and contingencies filling the rest. Geographic location, scope, and structural changes can tilt these ranges. Build a contingency of 10–20% for surprises such as outdated wiring, hidden leaks, or subfloor repair. Consider return on investment by balancing timeless features (durable flooring, quality cabinets, functional layout) with trend-forward elements you can refresh more easily (paint color, hardware, pendants).

Scope creep is the silent budget breaker. Lock a scope statement before you shop: Are you keeping the layout, moving a wall, relocating plumbing, or raising a ceiling? Structural changes and utilities relocation add design fees, permits, and longer timelines. Speaking of timelines, a typical mid-range project can run 6–12 weeks on site after permits and major materials are in hand; lead times for cabinets and custom counters often drive the schedule. Map the path: design and drawings, permit submission, ordering long-lead items, demolition, rough-in work, inspections, drywall, cabinets, counter templating, finish plumbing/electrical, and punch list.

Use a simple priority matrix to stay decisive when choices multiply:

• Must-haves: code-compliant wiring and GFCI protection, adequate lighting, durable work surfaces

• Nice-to-haves: an island with seating, pantry wall, under-cabinet lighting

• Future upgrades: integrated accessories, specialty inserts, secondary prep sink

This structure helps you cut or defer items without compromising safety or core functionality.

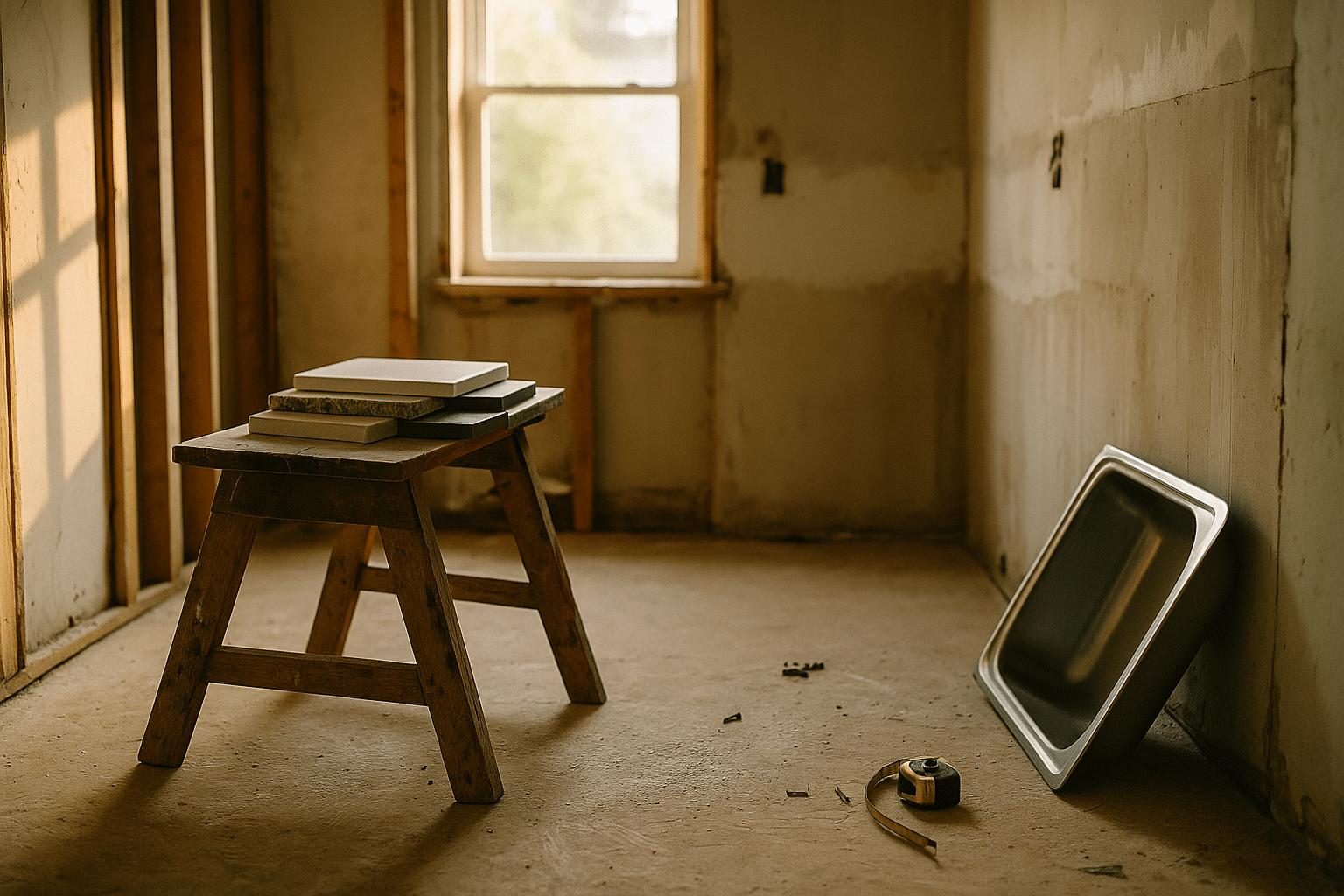

Finally, assemble a paper trail. Capture measurements, photos, inspirational images, and a spreadsheet of selections with model descriptions, dimensions, and finish codes. Clear documentation shortens meetings, reduces mistakes, and protects your budget when change orders appear.

Layout & Space Planning: Flow, Ergonomics, and Safety

Layout determines daily comfort more than any finish. Two planning philosophies guide most kitchens: the classic “work triangle” (sink, cooktop, refrigerator) and modern “work zones” (prep, cooking, cleaning, storage, serving). The triangle is efficient for compact kitchens; zones scale better for multi-cook or open-plan spaces. Start with accurate measurements of walls, windows, doors, ceiling height, and existing utilities. Sketch major elements and check clearances before committing to cabinet sizes.

Aisle width is foundational. Aim for about 36 inches for a one-cook galley, 42 inches for active cooking zones, and up to 48 inches if two people regularly work back-to-back. Provide landing zones: about 24 inches of counter next to the sink, ideally 12 inches on each side of a cooktop, and roughly 15 inches near the refrigerator and wall ovens. Leave 30–48 inches of clear space in front of appliance doors so they can open fully without blocking circulation. Standard counter height is about 36 inches; consider a 30–33 inch seated-height section for baking or accessibility. Toe kicks of roughly 3.5 inches deep by 4 inches high reduce back strain during long prep sessions.

Compare common layouts:

• Galley: efficient and budget-friendly, ideal for narrow spaces; limited room for socializing

• L-shape: flexible, supports a small island, good sightlines

• U-shape: abundant storage and counter, but watch inside-corner access

• Island: great for prep and seating; ensure aisles meet clearance targets

• Peninsula: strong option when space cannot fit a freestanding island

Island sizing deserves attention. A comfortable island with seating often needs around 24 inches of width per stool and an overhang of 12 inches; reinforce the countertop if the overhang exceeds manufacturer guidance. For appliances, check typical footprints: a 30–36 inch range, a 24-inch dishwasher, and varying refrigerator depths. Built-in or counter-depth units improve circulation in tight aisles. Door swings and traffic patterns should not cross hot zones; relocating a doorway can be more effective than squeezing in another cabinet.

Safety and comfort go hand in hand. Provide task lighting over prep areas to reduce shadows from upper cabinets. If possible, separate the cleanup sink from the main prep area so helpers can load dishes without interrupting cooking. For accessibility, target a 60-inch turning diameter in open areas and consider pull-down shelves and lever-style handles. Plan ventilation paths early; a direct duct run with minimal turns improves performance and reduces noise. With a well-tested layout on paper, every trade that follows works faster and with fewer surprises.

Materials and Finishes: Durability, Maintenance, and Style

Materials set the tone and the workload of your kitchen. Begin with cabinets, the largest visual and budgetary element. Cabinet boxes commonly use plywood or particleboard; plywood offers strong screw-holding and moisture resilience, while modern high-density particleboard can be stable and cost-effective. Frameless construction maximizes interior space and provides a sleek look; framed construction can feel more traditional and can be slightly more forgiving during installation. Finish choices include painted (crisp color options, may show wear sooner) and stained (showcases grain, hides minor dings). Durable hardware—full-extension, soft-close slides and hinges—protects doors and drawers from daily stress.

Countertops balance aesthetics with care requirements. Consider the trade-offs:

• Natural stone: unique patterns and heat tolerance; periodic sealing and potential for etching depending on the stone

• Engineered stone: consistent color and strong stain resistance; not fully heat-proof

• Solid surface: repairable scratches and seamless sinks; can be sensitive to heat

• Laminate: budget-friendly and design-forward patterns; vulnerable to cuts and heat

• Butcher block: warm, renews with sanding; needs regular oiling and is sensitive to moisture

• Stainless steel: professional vibe and hygienic; shows scratches and fingerprints that develop a patina

Flooring must survive spills, grit, and chair movement. Porcelain tile is hard-wearing and water-resistant, with a wide range of textures; use grout with stain-resistance and consider epoxy options for heavy-use zones. Luxury vinyl plank delivers comfort underfoot and strong water resistance, with realistic wood or stone visuals. Engineered wood offers warmth and can be more stable than solid wood over conditioned spaces; protect high-traffic areas with mats and felt pads. For walls, ceramic or porcelain tile remains a reliable backsplash choice; glass adds light play; stone demands sealing. Choose a grout color that supports easy maintenance and consistent appearance.

Think beyond looks to performance and health. Low-VOC paints and finishes help indoor air quality. Wood from responsibly managed sources supports sustainability goals. Water-saving faucets around 1.5 gpm reduce consumption without sacrificing function, and a deep, single-bowl sink simplifies cleaning large pots. Pair it with a high-arc faucet and a pull-down sprayer for reach and control. For handles and knobs, test grip comfort; small details drive perceived quality every day.

Before ordering, assemble a “materials mockup”: set your cabinet finish, counter sample, flooring swatch, and backsplash tile together under natural light to confirm undertones and texture. Capture a photo at different times of day. This simple step prevents mismatches and helps ensure the room feels cohesive, not assembled from catalog pages.

Systems that Make It Work: Electrical, Lighting, Plumbing, and Ventilation

Behind clean lines and glossy surfaces, systems do the heavy lifting. Electrical upgrades often top the list. Many kitchens need multiple 20-amp small-appliance circuits for countertops, with receptacles spaced so no point along the counter is more than about 24 inches from an outlet. Include GFCI protection for wet areas and AFCI where required. Provide dedicated circuits for high-draw appliances like dishwashers, disposals, wall ovens, and microwaves. Plan outlet placement thoughtfully—inside appliance garages or island ends—for convenience without visual clutter. Coordinate rough-in heights with backsplash tile layouts to avoid awkward cuts.

Layer lighting for comfort and safety. A practical target for ambient lighting is roughly 20 lumens per square foot, with task lighting over counters closer to 50 lumens per square foot. Warm-white lamps around 2700–3000K create a welcoming tone; a high color rendering index (around 90 or above) reveals true food and finish colors. Under-cabinet strips or pucks eliminate shadows; recesseds or a low-glare surface-mount fixture provide general light; accent lighting inside glass-fronts adds depth. Put lights on separate dimmable zones to adapt from breakfast calm to dinner prep focus.

Plumbing updates should consider both supply and drainage. Add shut-off valves that are easy to reach. If moving the sink, confirm venting options and adequate slope—about 1/4 inch per foot for typical drain runs—to keep water moving quietly. A deep sink reduces splashing; sound-deadening pads tame noise. Consider a water filter or a separate beverage faucet at the sink to free refrigerator space. Quiet dishwashers pair well with soft rubber isolation underlayment to reduce vibration through cabinetry.

Ventilation protects air quality and finishes. Sizing depends on the cooking equipment and configuration; common guidelines include around 1 CFM per 100 BTU of total gas burner output, or roughly 150–200 CFM per linear foot of electric or induction cooktop. Island installations typically need higher capture to overcome cross breezes. Keep duct runs short, smooth, and as straight as possible, exhausting outdoors rather than recirculating when feasible. In some jurisdictions, hoods at or above about 400 CFM may trigger make-up air requirements; plan early so mechanical components work together. Noise matters—lower sone ratings improve conversation and encourage consistent use.

Finally, coordinate all systems on a single reflected ceiling and wall elevation plan. Mark light locations, switch legs, outlet heights, plumbing rough-ins, and the hood duct path. This drawing becomes the site’s source of truth, reducing field changes and keeping the job on schedule.

Conclusion and Next Steps: From Plan to Punch List

Execution turns drawings into dinner. Start by ordering long-lead items—cabinets, custom counters, select fixtures—before demolition begins. A typical sequence flows like this: demolition and protection, framing and subfloor repairs, rough electrical and plumbing, inspections, insulation if required, drywall and prime, flooring (or prep), cabinets, counter templating and fabrication, backsplash and finish trim, paint touch-ups, and final plumbing and electrical trims. Building inspections slot in after rough-in and again at final. Keep a weekly site meeting to track progress and resolve questions quickly.

Choosing help is as vital as choosing tile. Interview at least three licensed contractors or trades, compare detailed, apples-to-apples bids, and ask for proof of insurance. Solid contracts should list the scope of work, clear inclusions and exclusions, payment schedule tied to milestones, warranty terms, and a change-order process. Check references from recent projects and, if possible, visit a job in progress to gauge site cleanliness and communication style. Small cues—labeled boxes, clean cut lines, protected floors—predict outcomes.

Quality control is easier with checklists. Before countertop templating, confirm cabinets are level and secured; after installation, verify doors align and drawers run smoothly. Test GFCI/AFCI devices, check that every light switch controls the intended fixture, and run water at each connection while inspecting for leaks. For ventilation, feel for strong capture at the front burners and verify the exterior cap opens freely. Build a punch list in writing with photos and due dates; withhold a reasonable final payment until items are completed.

Cost control does not mean cutting corners. Save smart by keeping your layout when possible, selecting standard cabinet sizes, mixing premium and value surfaces (for instance, a standout island paired with more economical perimeter counters), and installing durable, midrange fixtures that are well-regarded. Avoid false economies: inadequate lighting, weak ventilation, or noncompliant wiring will cost more in the long run. Keep a 10–20% contingency untouched until needed, and document every decision to prevent rework.

Most importantly, align the remodel with the life you live. If you batch-cook on weekends, prioritize uninterrupted prep runs, deep sinks, and sturdy, easy-clean counters. If you entertain, plan generous circulation and seating that invites guests to linger. With a grounded plan, disciplined execution, and clear quality standards, your remodel becomes less of a leap and more of a series of steady, confident steps toward a kitchen that works beautifully day after day.