Advanced Ultrasonic Flaw Detection Technology

Introduction to Ultrasonic Flaw Detection

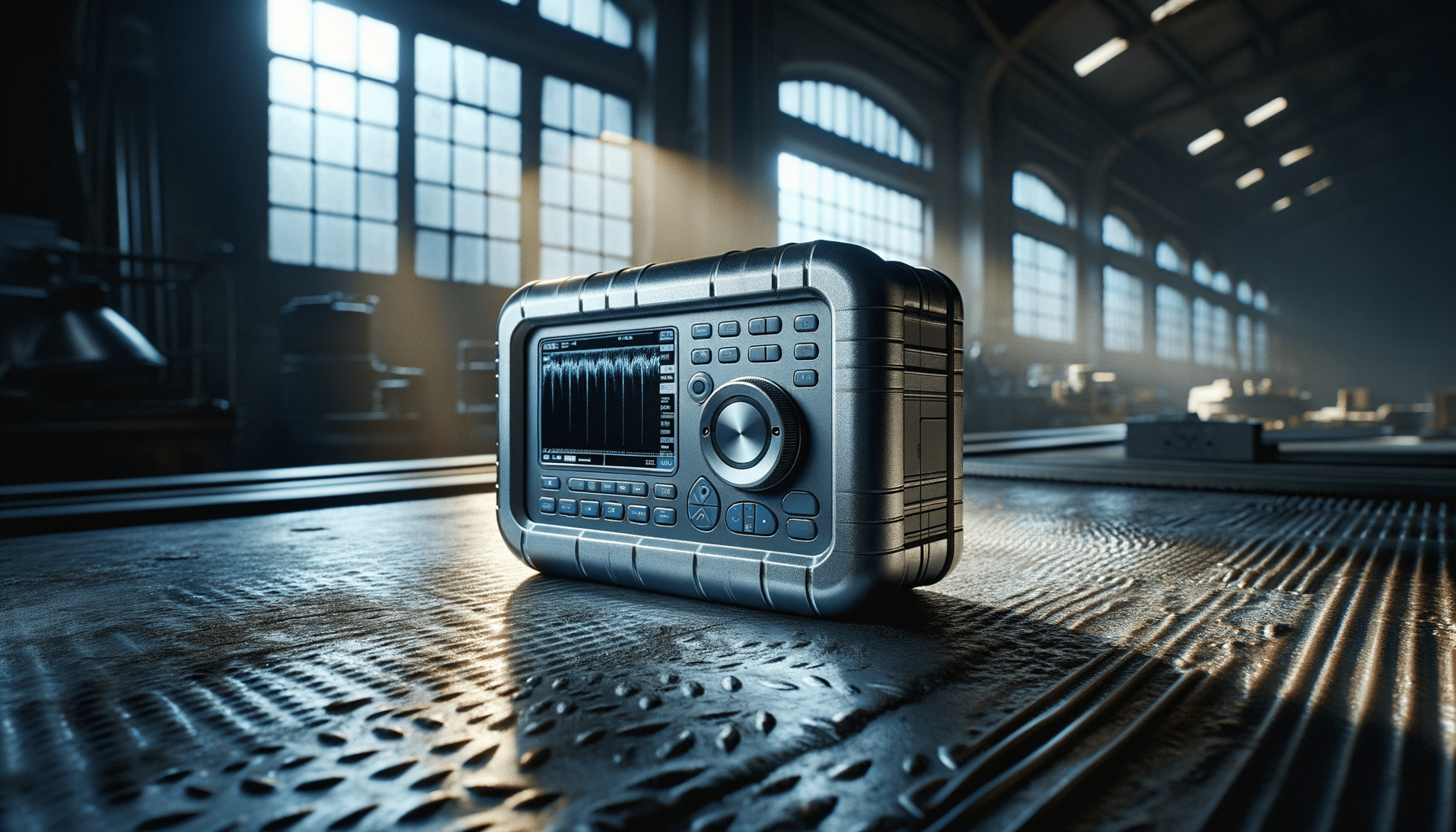

Ultrasonic flaw detection is a critical technique used across various industries to ensure the integrity and safety of materials. By utilizing high-frequency sound waves, this method can detect internal and surface defects in metals, welds, and industrial components. Its importance is underscored by the need for reliable and non-destructive testing methods in sectors like aerospace, automotive, and construction, where safety and quality are paramount.

How Ultrasonic Flaw Detection Works

The process of ultrasonic flaw detection involves transmitting ultrasonic waves into a material. The interaction of these waves with the material’s internal structure provides insights into its condition. When these waves encounter a flaw, such as a crack or void, they reflect back to the transducer, which then interprets the signals to identify the flaw’s size and location.

Key components of this technique include:

- Transducer: Converts electrical energy into sound waves and vice versa.

- Couplant: A medium that facilitates efficient transmission of ultrasonic waves between the transducer and the test object.

- Display unit: Visualizes the data, often in the form of an A-scan or B-scan, to interpret the results.

Understanding the physics behind ultrasonic wave propagation is crucial for accurate flaw detection. Factors such as frequency, material density, and wave velocity all play significant roles in determining the method’s effectiveness.

Applications and Industries Benefiting from Ultrasonic Flaw Detection

Ultrasonic flaw detection is widely used in industries where material integrity is crucial. In aerospace, it helps ensure that aircraft components are free from defects that could lead to catastrophic failure. Similarly, in the automotive industry, it is used to inspect engine components and structural parts for flaws that could compromise safety.

Other notable applications include:

- Construction: Inspecting welds and structural steel for defects.

- Oil and Gas: Ensuring the integrity of pipelines and pressure vessels.

- Manufacturing: Quality control of metal parts and assemblies.

The versatility of ultrasonic flaw detection makes it an invaluable tool for maintaining safety and quality standards across these sectors.

Advantages and Limitations of Ultrasonic Flaw Detection

One of the primary advantages of ultrasonic flaw detection is its non-destructive nature, allowing for inspection without damaging the test object. It is highly sensitive, capable of detecting even small flaws, and provides immediate results. Additionally, it can be used on a wide range of materials and thicknesses.

However, there are limitations to consider. The technique requires skilled operators to interpret data accurately, and surface conditions can affect the quality of results. Couplant application and transducer positioning must be precise, which can be challenging in complex geometries.

Despite these challenges, ongoing advancements in technology continue to enhance the capabilities and ease of use of ultrasonic flaw detection systems.

Future Trends in Ultrasonic Flaw Detection Technology

The future of ultrasonic flaw detection holds promising advancements, particularly with the integration of digital technologies. Developments in data processing and imaging software are enhancing the accuracy and efficiency of flaw detection. Automation and robotics are also being increasingly employed to perform inspections in hard-to-reach areas, reducing human error and improving safety.

Moreover, the use of artificial intelligence and machine learning algorithms is set to revolutionize the interpretation of ultrasonic data, providing more reliable and faster assessments. These trends indicate a shift towards more sophisticated and user-friendly systems that will broaden the application scope of ultrasonic flaw detection.

Conclusion

Ultrasonic flaw detection remains a cornerstone of non-destructive testing, ensuring the safety and reliability of materials across various industries. As technology advances, the technique is becoming more accessible and efficient, offering even greater potential for ensuring the quality and safety of critical components. For industries that rely on the integrity of their materials, ultrasonic flaw detection will continue to be an essential tool.