Custom Conveyor Solutions for Warehouses in Mexico

Introduction to Custom Conveyor Solutions

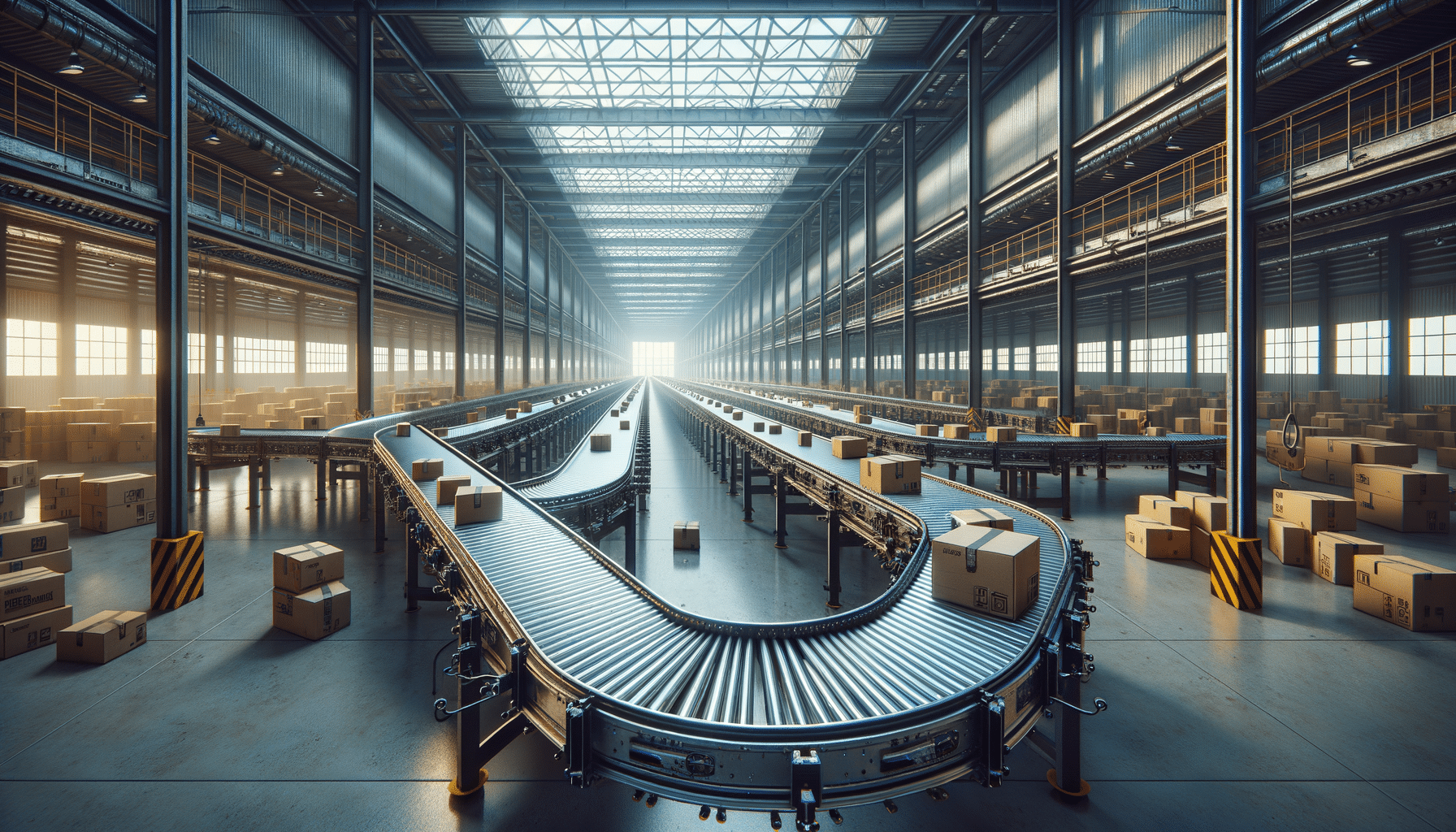

In the bustling world of logistics and warehousing, efficiency is key. The need for smooth, rapid, and reliable material handling solutions has never been more crucial. Custom conveyor solutions offer a tailored approach to meet the specific needs of warehouses, particularly in Mexico, where industrial growth is on the rise. These solutions are designed to optimize workflow, reduce operational costs, and enhance productivity. By investing in custom conveyors, warehouses can ensure that their operations run seamlessly, addressing unique logistical challenges with precision.

Benefits of Custom Conveyor Solutions

Custom conveyor solutions bring a host of benefits to warehouse operations. Firstly, they are tailored to fit the specific layout and operational requirements of a warehouse, which means they can be designed to handle various types of materials, from lightweight packages to heavy pallets. This adaptability ensures that the conveyor systems can cater to diverse industry needs.

Moreover, these solutions enhance efficiency by reducing manual handling and minimizing the risk of damage during transit. This leads to faster processing times and improved throughput, which are essential for meeting customer demands in a timely manner. Additionally, custom conveyors contribute to workplace safety by reducing the physical strain on employees and lowering the risk of workplace injuries.

- Optimized workflow tailored to specific needs

- Increased efficiency and reduced processing times

- Enhanced safety and reduced manual handling

Types of Custom Conveyor Systems

There are various types of custom conveyor systems available, each designed to address specific operational requirements. Belt conveyors are among the most common, ideal for transporting goods of varying sizes and shapes. They are versatile and can be configured to suit different layouts, including straight paths and curves.

Another popular choice is the roller conveyor, which is excellent for handling heavier loads. These systems use a series of rollers to move items along the conveyor path, making them suitable for transporting bulky materials. For warehouses dealing with fragile items, overhead conveyors offer a solution that keeps goods elevated, reducing the risk of damage.

- Belt conveyors for versatile transport

- Roller conveyors for heavy loads

- Overhead conveyors for delicate items

Implementing Custom Conveyor Solutions in Mexico

Implementing custom conveyor solutions in Mexican warehouses involves a strategic approach that considers the unique challenges and opportunities within the region. Mexico’s growing industrial sector necessitates efficient logistics solutions to keep pace with demand. Custom conveyors can address these needs by providing scalable solutions that grow with the business.

One key factor in successful implementation is collaboration with local experts who understand the regional market and operational nuances. By working with professionals experienced in designing and installing conveyor systems, warehouses can ensure that their investment delivers maximum benefits. Additionally, considering local regulations and standards is crucial to ensure compliance and smooth operation.

- Strategic planning and collaboration with local experts

- Scalable solutions to accommodate growth

- Compliance with local regulations and standards

Conclusion: The Future of Warehouse Operations in Mexico

The future of warehouse operations in Mexico looks promising, with custom conveyor solutions playing a pivotal role in driving efficiency and growth. As the demand for rapid and reliable logistics continues to rise, these tailored systems will become increasingly essential. By investing in custom conveyors, warehouses can position themselves at the forefront of innovation, ensuring they meet the challenges of tomorrow with confidence.

Ultimately, the adoption of custom conveyor solutions represents a strategic move towards operational excellence. It empowers warehouses to streamline their processes, enhance their service delivery, and achieve a competitive edge in the dynamic logistics landscape.