Industrial and Workplace Safety Equipment

Introduction to Workplace Safety Equipment

In today’s industrial and commercial environments, ensuring the safety of employees is paramount. The use of appropriate safety equipment not only protects workers from potential hazards but also helps organizations comply with regulatory standards. Safety equipment ranges from personal protective gear to complex machinery designed to mitigate risk. Understanding the different types of safety equipment and their applications is crucial for maintaining a safe workplace.

Safety equipment serves as a barrier between workers and hazards, reducing the likelihood of injury or accidents. These tools are essential in industries such as construction, manufacturing, and chemical processing, where the risk of injury is high. By investing in quality safety equipment, businesses can foster a culture of safety and demonstrate their commitment to employee welfare.

This article will delve into various aspects of safety equipment, exploring how they contribute to workplace safety and compliance. We will cover personal protective equipment (PPE), fire safety tools, and equipment for specific industries, providing a comprehensive overview of the safety measures available to protect workers.

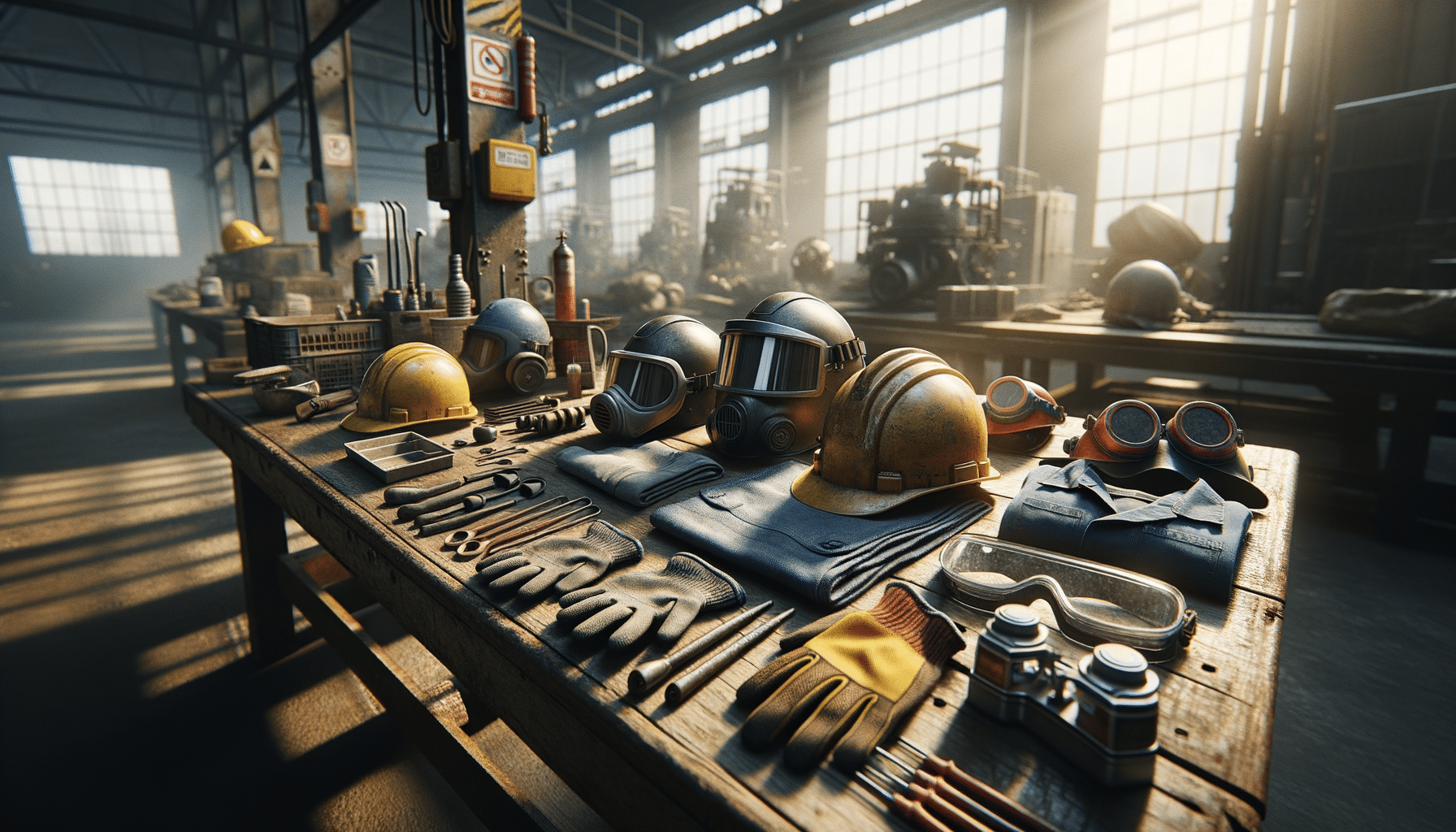

Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) is a cornerstone of workplace safety, providing the first line of defense against physical hazards. PPE includes a wide range of items such as helmets, gloves, goggles, and respirators, each designed to protect specific parts of the body. For instance, helmets safeguard against head injuries, while gloves protect hands from cuts and chemical exposure.

One of the critical aspects of PPE is its ability to be tailored to specific tasks and environments. For example, in environments where noise levels are high, ear protection like earmuffs or earplugs is essential. Similarly, in areas with airborne particulates, respirators or masks become necessary to ensure respiratory safety.

Proper usage and maintenance of PPE are vital to its effectiveness. Employers must ensure that PPE is not only available but also that employees are trained in its correct use. Regular inspections and maintenance of safety gear help in identifying wear and tear, ensuring that the equipment remains in optimal condition.

By prioritizing the use of PPE, businesses can significantly reduce workplace injuries and illnesses, creating a safer and more productive environment for all employees.

Fire Safety Equipment

Fire safety equipment is crucial in preventing and mitigating the effects of fire-related incidents in the workplace. This equipment includes fire extinguishers, smoke detectors, fire alarms, and sprinkler systems. Each component plays a vital role in early detection and response to fire hazards.

Fire extinguishers, for instance, are the most common firefighting tools available in workplaces. They come in various types, such as water, foam, carbon dioxide, and dry chemical extinguishers, each suitable for different classes of fires. Understanding the appropriate type of extinguisher for specific fire risks is essential for effective fire management.

Smoke detectors and fire alarms serve as early warning systems, alerting occupants to evacuate and take necessary precautions. Sprinkler systems, on the other hand, automatically activate to control and extinguish fires, minimizing damage and preventing the spread of flames.

Regular maintenance and testing of fire safety equipment are crucial to ensure their functionality in an emergency. Training employees on fire safety protocols, including the use of fire extinguishers and evacuation procedures, further enhances workplace safety.

Implementing comprehensive fire safety measures not only protects lives but also helps businesses avoid costly damages and disruptions.

Industry-Specific Safety Equipment

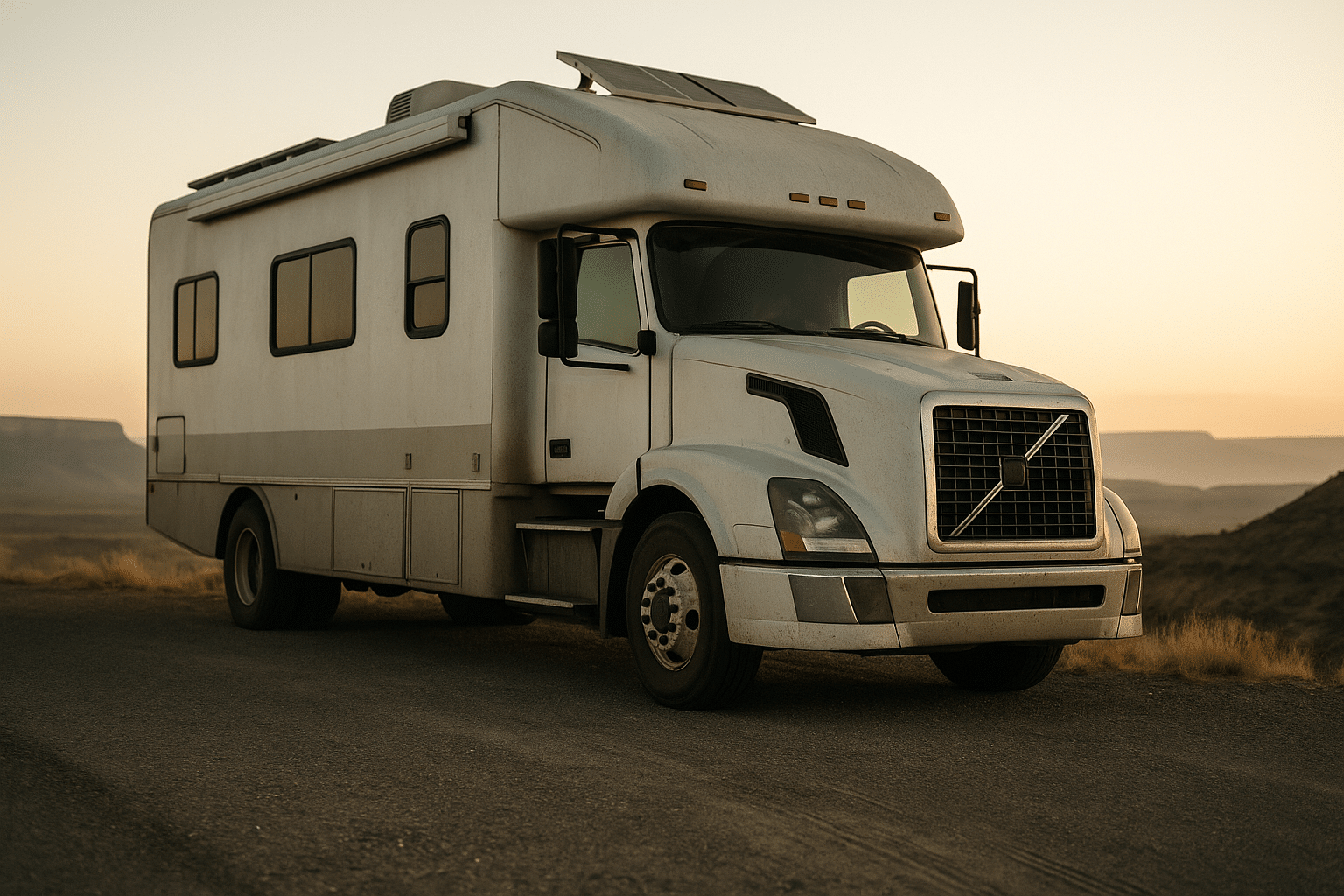

Different industries face unique safety challenges, requiring specialized equipment to address specific risks. For instance, the construction industry often deals with hazards such as falling objects and electrical risks, necessitating the use of hard hats, safety harnesses, and insulated tools.

In the chemical industry, the risk of exposure to hazardous substances is high. As such, safety equipment like chemical-resistant gloves, aprons, and full-face respirators are essential to protect workers from chemical burns and inhalation of toxic fumes.

Similarly, the food processing industry requires equipment that ensures both worker safety and product hygiene. This includes protective clothing, hairnets, and sanitization equipment to prevent contamination and ensure compliance with health regulations.

By understanding the specific safety needs of their industry, businesses can invest in the right equipment to protect their workforce and maintain operational efficiency.

Conclusion: The Importance of Investing in Safety Equipment

Investing in high-quality safety equipment is not just a legal obligation but a moral one. It reflects an organization’s commitment to its employees’ health and well-being. By providing the necessary tools and training, businesses can create a culture of safety that extends beyond compliance.

Incorporating safety equipment into workplace practices reduces the risk of accidents and injuries, leading to a more productive and motivated workforce. It also minimizes financial losses associated with workplace incidents, such as medical expenses and legal liabilities.

Ultimately, prioritizing safety through the use of appropriate equipment fosters a positive work environment where employees feel valued and protected. This not only enhances company reputation but also contributes to long-term success and sustainability.