Prefab Log Cabins: Customization, Efficiency, and Assembly

Introduction to Prefab Log Cabins

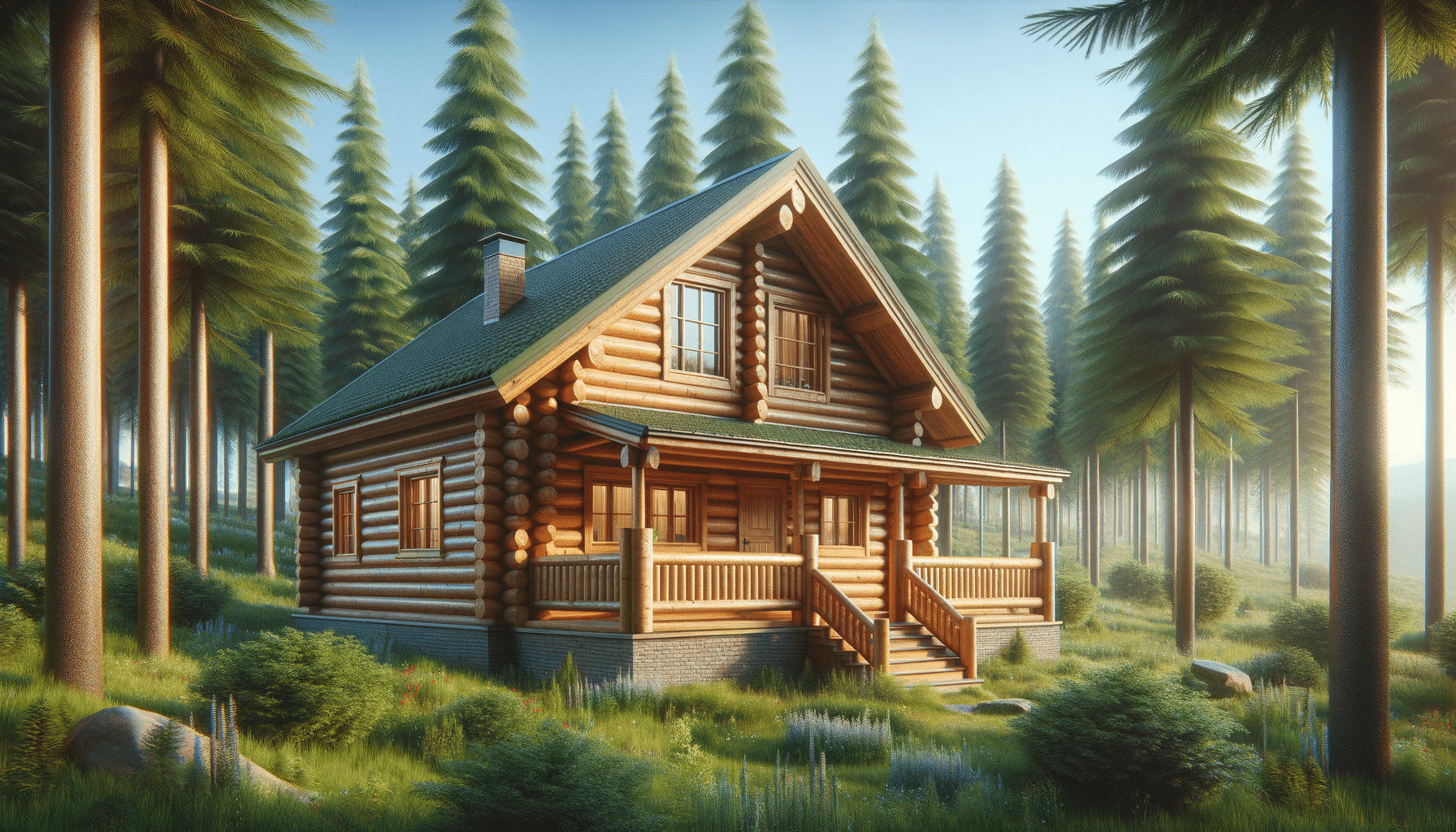

In recent years, prefab log cabins have surged in popularity as an innovative and eco-friendly housing option. These structures combine traditional aesthetics with modern construction techniques, offering a unique blend of rustic charm and contemporary efficiency. Prefab log cabins are pre-manufactured in sections, making them quicker to assemble and often more cost-effective than traditional log cabins. This article delves into the various aspects of prefab log cabins, focusing on customization options, energy-efficient construction, and streamlined assembly methods.

Strategies for Customization

One of the most appealing aspects of prefab log cabins is the wide range of customization options available to homeowners. Customization allows individuals to tailor their cabins to meet specific needs and preferences, whether it involves selecting the type of wood, choosing floor plans, or incorporating unique architectural features. Here are some strategies for customization:

- Material Selection: Homeowners can choose from a variety of wood types, each offering distinct textures and colors.

- Floor Plans: Prefab log cabins can be tailored with different layouts, from single-room designs to multi-bedroom configurations.

- Architectural Additions: Options such as porches, skylights, and additional rooms can enhance both functionality and aesthetics.

By utilizing these strategies, homeowners can create a space that reflects their personal style and meets their living requirements, all while maintaining the inherent beauty of log construction.

Energy-Efficient Construction

Energy efficiency is a critical consideration in modern construction, and prefab log cabins excel in this area. The design and materials used in these cabins can significantly reduce energy consumption, making them an environmentally friendly choice. Key elements of energy-efficient construction in prefab log cabins include:

- Insulation: High-quality insulation materials ensure that these cabins maintain a comfortable temperature throughout the year, reducing heating and cooling costs.

- Sustainable Materials: Many manufacturers source wood from sustainable forests, which helps reduce the environmental impact.

- Sealing and Weatherproofing: Proper sealing techniques prevent drafts and moisture intrusion, further enhancing energy efficiency.

By integrating these energy-efficient features, prefab log cabins not only lower utility bills but also contribute to a more sustainable living environment.

Streamlined Assembly Methods

The assembly process for prefab log cabins is designed to be efficient and straightforward, minimizing construction time and labor costs. These cabins are pre-manufactured in sections, which are then transported to the site for assembly. Here’s how the process typically unfolds:

- Pre-Manufacturing: Cabin components are fabricated in a controlled factory setting, ensuring precision and quality.

- Site Preparation: The site is prepared in advance, with foundations laid and utilities set up to receive the cabin sections.

- Assembly: Skilled workers assemble the pre-manufactured sections on-site, often completing the process in a matter of days.

This streamlined approach not only reduces construction time but also minimizes the environmental disruption typically associated with traditional building methods.

Conclusion: The Future of Prefab Log Cabins

The future of prefab log cabins looks promising as more people seek sustainable and customizable housing solutions. With advances in technology and an increasing emphasis on eco-friendly living, prefab log cabins offer a compelling option for modern homeowners. These cabins blend timeless design with innovative construction techniques, providing a harmonious balance between nature and contemporary living. As the demand for such structures grows, we can expect to see even more innovations in customization, energy efficiency, and assembly methods, further solidifying their place in the housing market.